Joint Development of a Highly Stable Magnetorheological Fluid (MR Fluid) That Does Not Sediment Even After Long Storage

Wed, Apr 1, 2020-

Tags

Raising Expectations for Application to Mechanical Control Field, Including Robots

Nippon Paint Holdings Co., Ltd. (NPHD) (Head office: Kita-ku, Osaka City; Chairman, President and CEO: Masaaki Tanaka) and Waseda University (Address: Shinjuku-ku, Tokyo; President: Aiji Tanaka) have joined the Feasibility Study Program to discover promising engineering seeds promoted by the New Energy and Industrial Technology Development Organization (NEDO) (Head office: Kawasaki City, Kanagawa; Chairman: Hiroaki Ishizuka). Their joint effort has resulted in development of a highly stable magnetorheological fluid (MR fluid)1 that does not sediment after long storage.

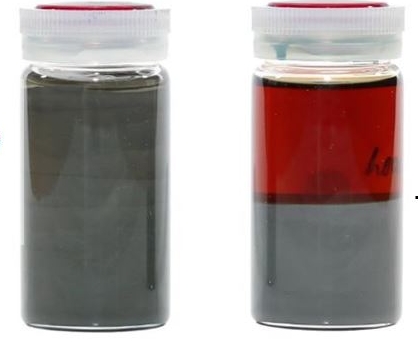

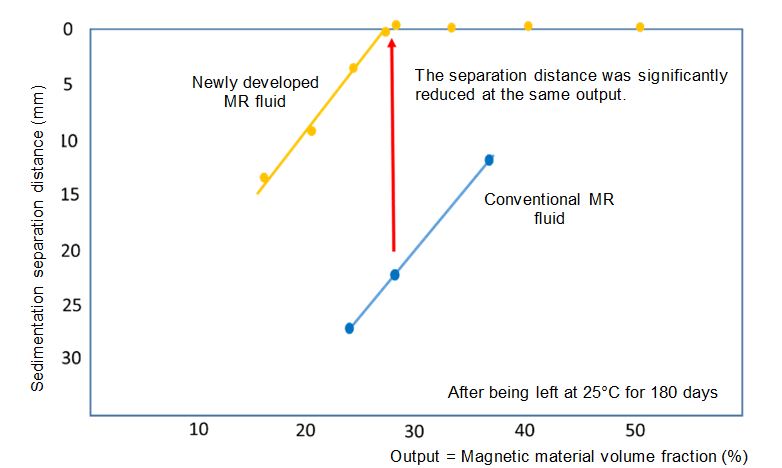

An MR fluid is a type of fluid in which magnetic particles, including ferrous particles, are dispersed in a carrier fluid2 such as oil. With the ability to control various types of movements by applying external magnetic fields, MR fluid is expected for application to mechanical control field, including vehicle braking systems, vibration dampers3, and robot actuators4. However, there are challenges inherent with conventional MR fluid, because as magnetic particles in a carrier fluid tend to sediment, MR fluid may cause damage to equipment and destabilize its operationality after a long period of use. For this newly developed MR fluid, by exploiting NPHD’s expertise including its proprietary dispersion methods and stabilization techniques, a polyoxyethylene fatty acid amide derivative, which has a side chain5 to prevent the sedimentation of magnetic particles, was used as the carrier fluid, and nanoparticles with diameters of 20 to 300 nm were added to the carrier fluid. This is the first stable MR fluid that does not separate after being left stationary for six months (Figure 1), and produces high stress in response to external magnetic fields.

This achievement allows long-term use of the MR fluid, raising expectations for application to various types of mechanical control devices, including robots.

NPHD, NEDO and Waseda University will continue joint development of flexible actuators for robots through use of the newly developed MR fluid. Taking advantage of its knowledge concerning dispersion methods and stabilization techniques targeting particles such as pigments, accumulated through the development and production of paints, NPHD will continue its development efforts directed toward the commercialization of new MR fluids optimized for industrial machinery, and cultivate additional fields of applications.

Figure 1: Sedimentation Separation Comparison between Newly Developed MR Fluid (left) & Conventional MR Fluid (right) (after a lapse of 180 days). While the conventional MR fluid exhibits separation of magnetic particles, the new MR fluid maintains the state of dispersion.

1. Background of Development

A magnetorheological fluid (MR fluid) is a type of fluid in which magnetic particles, including ferrous particles, are dispersed in a carrier fluid such as oil, and its viscosity changes in reaction to an external magnetic field. The use of MR fluid can simplify vehicle braking systems and vibration dampers, increase speed reduction ratios, and improve inverse mobility. Electrical control of MR fluid can adjust its viscosity agilely. These characteristics raise expectations for the application of MR fluid to medical equipment, haptics6, VR (virtual reality) equipment, and many other fields.

There are challenges inherent with conventional MR fluid. As magnetic particles are relatively large, with diameters of several tens of micrometers, they sediment in the carrier fluid after storage for several months, thus causing damage to equipment and destabilizing its operationality. On the other hand, MR fluids using relatively small magnetic particles (several tens to several hundreds of nanometers) have been developed to prevent sedimentation, but small magnetic particles are not practical or cost-effective for industrial use because the small size reduces output, and fine particle materials themselves are costly.

Against this backdrop, NPHD, the NEDO and Waseda University jointly developed a highly stable MR fluid that does not sediment after long storage under the NEDO Advanced Research Program7.

2.Achievement due to This Development

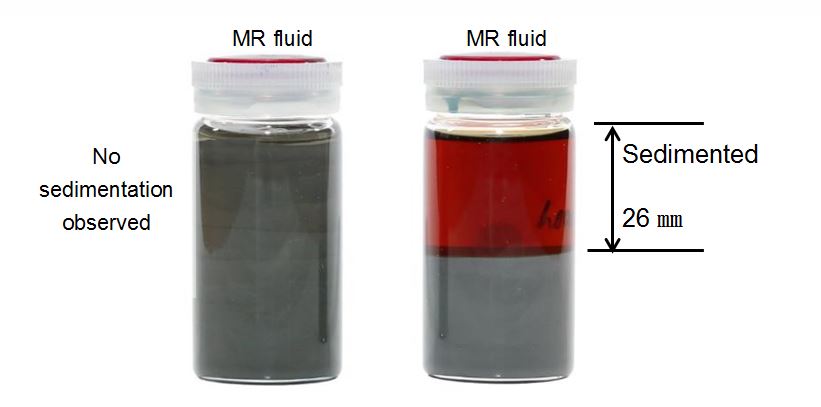

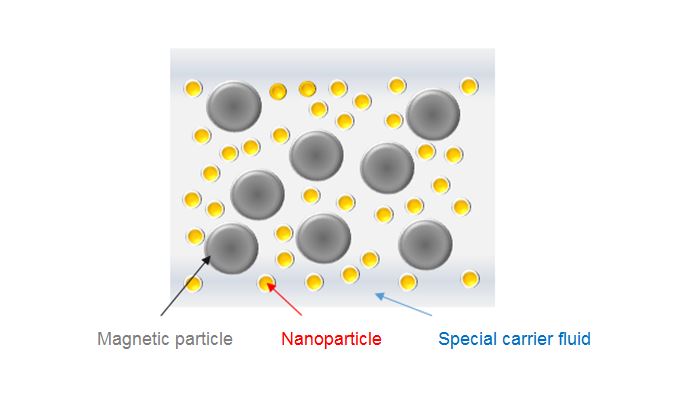

The new MR fluid is distinctive in using a polyoxyethylene fatty acid amide derivative (Figure 2), which has a side chain to prevent the sedimentation of magnetic particles, as the carrier fluid, with the addition of a certain amount of nanoparticles with diameters of 20 to 300 nm, which are smaller than magnetic particles and disperse in the carrier fluid (Figure 3), as well as large magnetic particles having diameters from several to 50 µm, which can produce high stress, as the main component. The polyoxyethylene fatty acid amide derivative and nanoparticles can prevent the sedimentation of large magnetic particles. These features enable preventing separation after being left stationary for six months, and production of high stress in response to external magnetic fields.

Figure 2: Polyoxyethylene Fatty Acid Amide Derivative

Figure 3: Conceptual Diagram of Newly Developed MR Fluid

Generally, the stress that an MR fluid generates in reaction to an external magnetic field increases in proportion to the concentration of magnetic particles dispersed in the fluid. However, when the concentration of magnetic particles exceeds a certain level, the magnetic particles do not disperse but coagulate. Contrary to that, the concentration of magnetic particles needs to be lowered for a smooth and soft output, but a low concentration tends to induce sedimentation. The newly developed MR fluid can apply to a wide scope of outputs as well as maintain high stability.

Figure 4: Output Scope and Stability (Prevention of Sedimentation Separation)

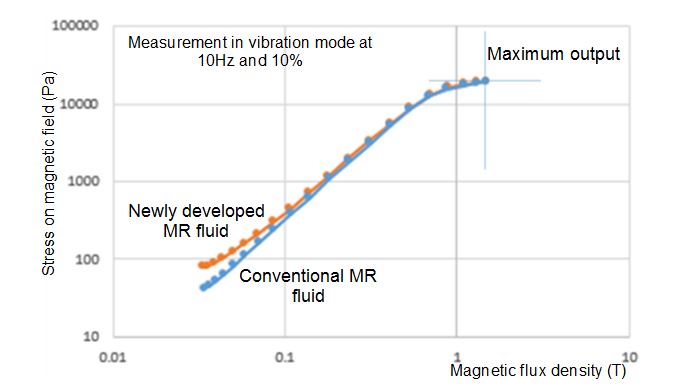

The new MR fluid can present stress to an external magnetic field (magnetic flux density) at the same level as for conventional MR fluid, and also produce a high maximum output.

Figure 5: Changes in Magnetic Viscoelasticity of MR Fluids (comparison between conventional MR fluid and the new fluid (30mT to 1.5T))

Notes

1. MR (Magneto Rheological) fluid

2. A medium with dispersed particles

3. Systems for absorbing the vibrations from earthquakes, etc.

4. Driving devices for converting energy into translational or rotational motion with hydraulic mechanisms or electric motors

5. A part in the molecular structure of an open-chain compound, which branches off from the longest chain of carbon atoms (main chain)

6. Technology that provides a force, vibration, motion, etc. to a user so that the user can experience a skin sensation as feedback

7. NEDO Feasibility Study Program: Innovative MR material and drive mechanism fusion research and development to achieve next-generation industrial soft robots in the new industry creation and new technology feasibility study program under the NEDO feasibility study program (Research period: 2018 to 2020).

More about MR fluid

Principle

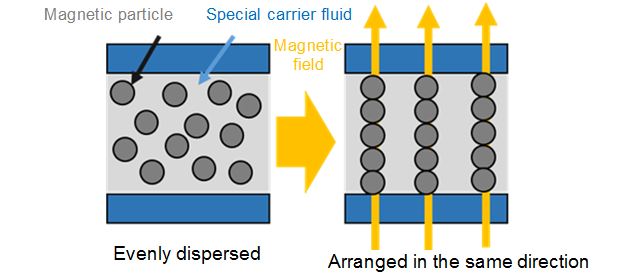

Applying an external magnetic field can control the arrangement of magnetic particles and change the viscosity of the fluid.

Figure 6: Principle of MR Fluid Movement

Application

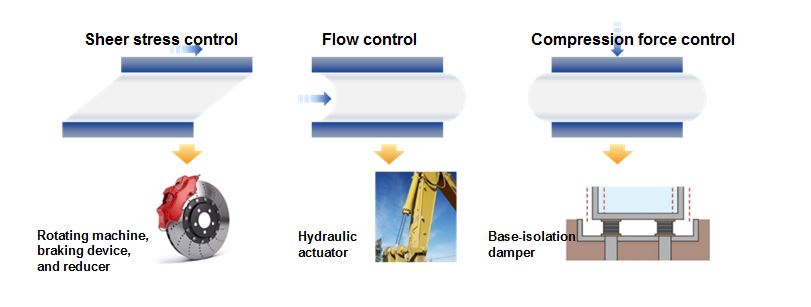

Applying an external magnetic field to control magnetic particles in the MR fluid enables various kinematic controls, including sheer stress, flow, and compression force, so its application to rotating machines, braking devices, reducers, hydraulic actuators, and base-isolation dampers, etc. is currently being studied.

Figure 7: MR Fluid Application Examples