Waseda Frontline Research Vol.12-2: Heat pumps converting ambient heat into energy

Mon, Dec 19, 2016-

Tags

Part 2: Changing the world with a new air conditioning system

Heating systems control researcher

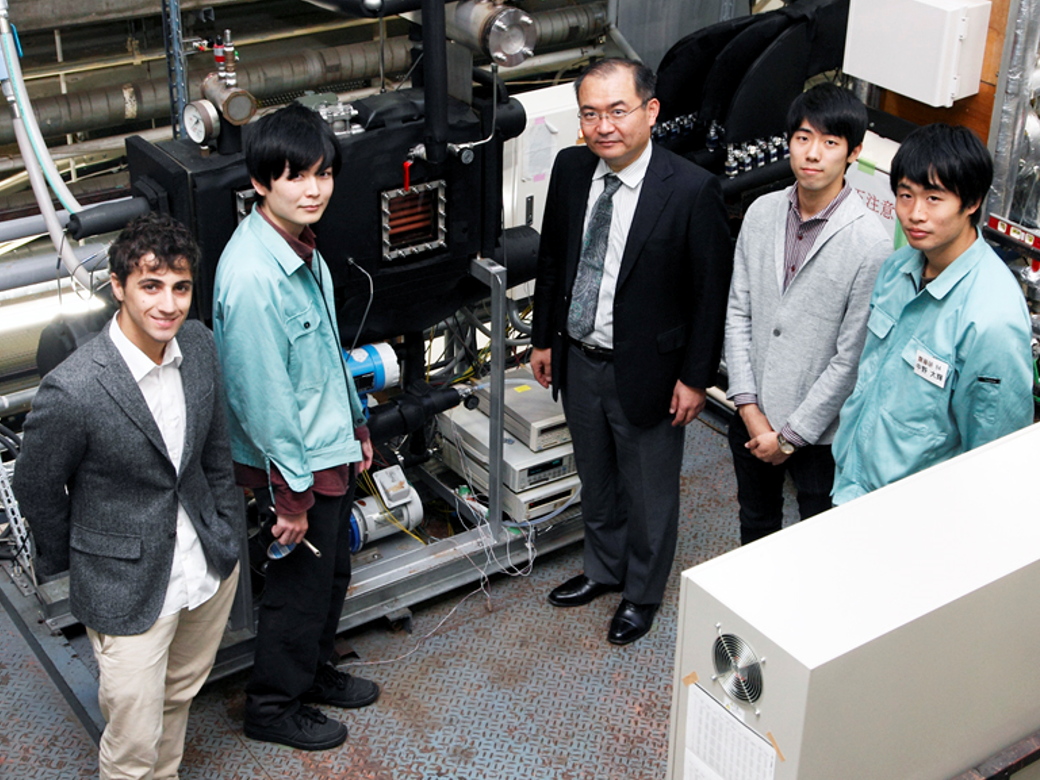

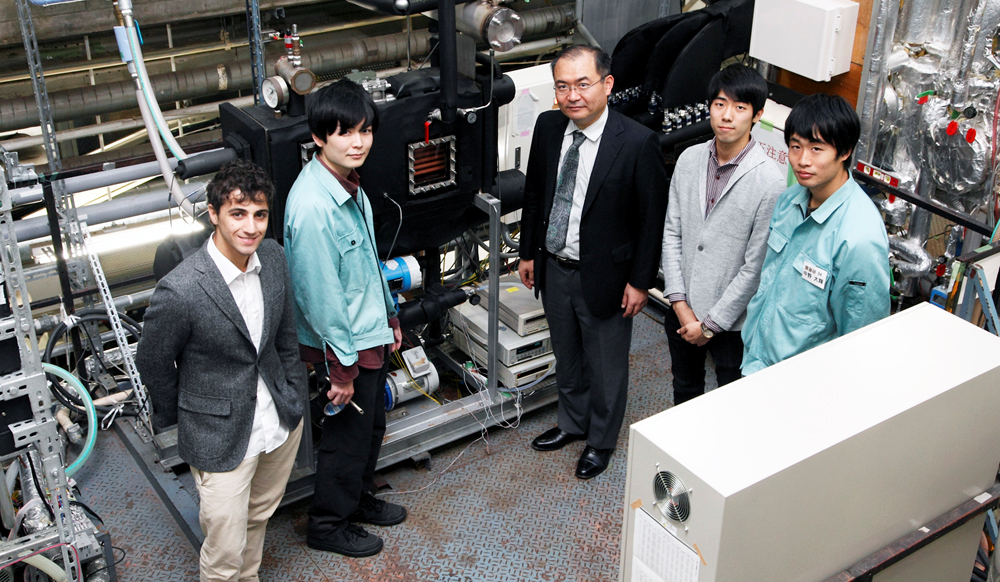

Professor Kiyoshi Saito, Department of Applied Mechanics and Aerospace Engineering, School of Fundamental Science and Engineering, Faculty of Science and Engineering

In effect since November 4, 2016, Japan’s greenhouse gas reduction target in the Paris Agreement is to cut “26% off the FY2013 level by FY2030.” Meanwhile, the amount of CO2 emissions from the civilian sector (operations, households) has increased dramatically compared to the flat and slightly increasing industrial and the transport sectors. This is a major problem. Professor Kiyoshi Saito’s goal is to address this issue by designing a highly-efficient air conditioning system that combines a heat exchanger and a heat pump. In the second part of the interview, he speaks about his future research. Part 1 is available here. (Interview date: October 24, 2016)

In effect since November 4, 2016, Japan’s greenhouse gas reduction target in the Paris Agreement is to cut “26% off the FY2013 level by FY2030.” Meanwhile, the amount of CO2 emissions from the civilian sector (operations, households) has increased dramatically compared to the flat and slightly increasing industrial and the transport sectors. This is a major problem. Professor Kiyoshi Saito’s goal is to address this issue by designing a highly-efficient air conditioning system that combines a heat exchanger and a heat pump. In the second part of the interview, he speaks about his future research. Part 1 is available here. (Interview date: October 24, 2016)

Industries and academia collaborating to reduce CO2 emissions

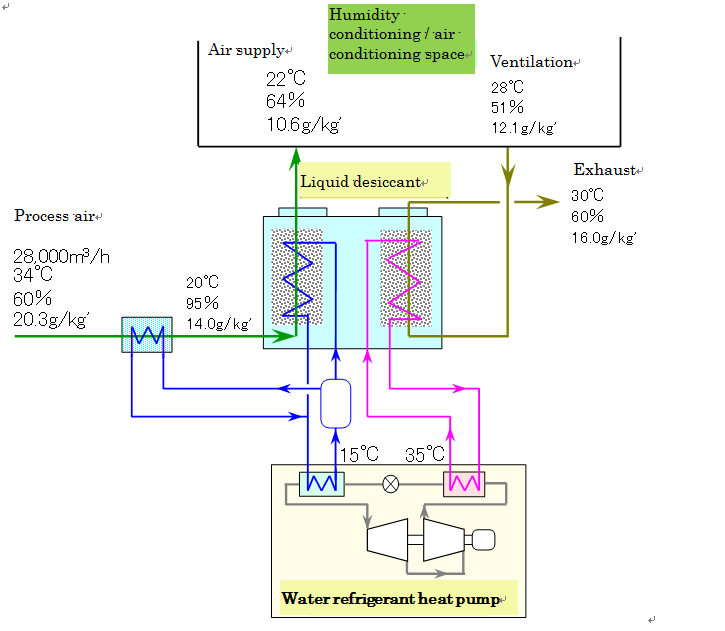

We are proceeding with the Ministry of Environment’s new technology innovation and demonstration project “Development of high energy conditioning via combination of liquid desiccant and water refrigerant heat pump.” This project aims to develop a new commercial air conditioning system and reduce CO2 emissions by more than 40%.

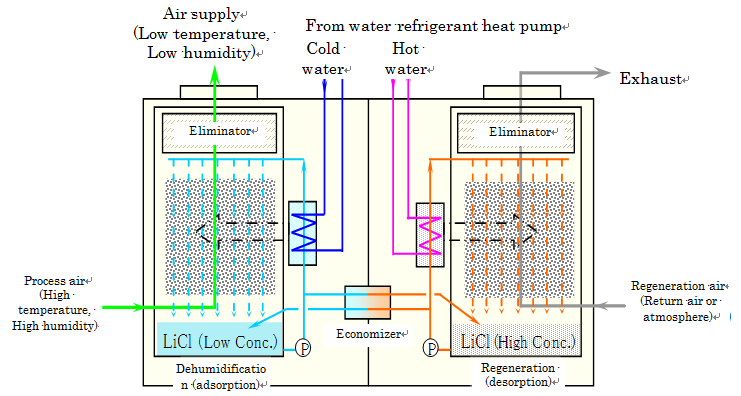

Figure 5: Overall configuration of a highly efficient air conditioning system, composed of a liquid desiccant dehumidifying air conditioning system and a water refrigerant heat pump

The liquid desiccant dehumidifying air conditioning system and the water refrigerant heat pump are the core technologies for this project. In fact, the air conditioner itself can be realized with a single heat pump. Since the heat pump uses ambient environment heat to control the temperature by expansion and compression only, it essentially has high energy efficiency. Additionally, it does not pollute air because there is no combustion. However, when adjusting the temperature and humidity with the heat pump alone, the operation becomes inefficient because humidity is first removed by cooling before raising the temperature to the desired level. To address this problem, the temperature and humidity are adjusted in two stages with the heat pump and humidity desiccant, respectively.

Nonetheless, there are also problems with this method. For example, the whole system becomes large for it combines two types of devices, and both the dehumidification and the air conditioning are operated by the heat pump’s heat control only. Therefore, if the control balance collapses, it could result in inefficiency.

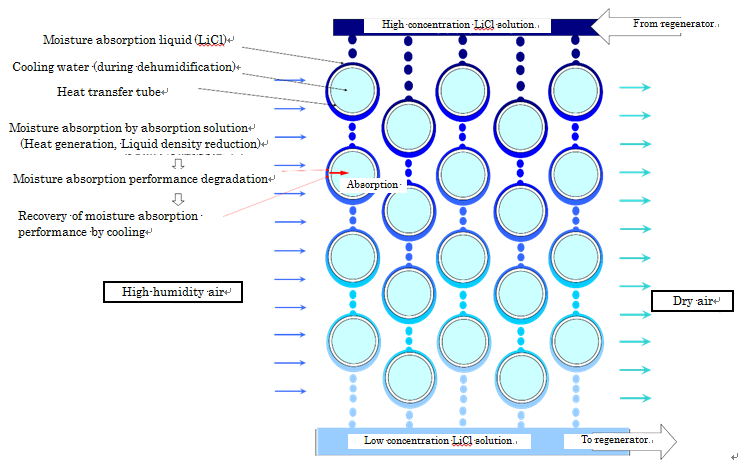

To make the system compact, particularly the liquid desiccant, we are working on a new type of 3-fluid heat exchanger which can undertake heat and mass exchanges of three kinds of fluids simultaneously: process air, moisture absorbing liquid and its heating/cooling medium. This technology, which has been studied with Dyna-Air Co. Ltd. for about five years now, is now 50-60% complete in development. This is a big responsibility because the results will determine the size of the whole air conditioning system.

Figure 6: Configuration of the liquid desiccant dehumidifying air conditioning system

Figure 7: 3 fluid heat exchanger (left-side enlarged view of FIG. 2), a 3-dimensional structure where steam flows through the heat transfer tubes from the front of the figure to the back, the dehumidifying liquid is dropped in the vertical direction, and the air flows in the left-right direction

Improving the comfort and safety of underground spaces

In the future, we would like to introduce a new commercial air conditioning system in underground spaces for two reasons. First, in current underground spaces, air-conditioners are run at rated operation (in terms of equipment performance), and efficiency and comfort have become secondary. The new air conditioning system could contribute to improving this point. The other reason is for safety. Fluorocarbon refrigerants, such as R410A used in air conditioners, are gradually being replaced by materials such as R32 with low global warming potential. However, they are flammable and may cause significant damage if an accident occurs. The water refrigerant heat pump that constitutes this new air conditioning system is a product that brings together the best of Kawasaki Heavy Industries Ltd.’s technology without using Freon refrigerant. It is safe so that even if the air conditioning system is damaged due to reasons such as earthquakes, only water will leak.

Earning high praise, Japan’s air conditioners are the world’s top performers. On the other hand, I think we are somewhat behind the curve regarding customization, in which Chinese and Korean companies are good at. For example, in my laboratory, there are a lot of international students from Southeast Asia. They say that heating function is unnecessary because the temperature and humidity are high in their home countries throughout the year. I hope to understand the features and needs of each country, and bring higher quality, Japanese products to the world.

Noticing potential research areas of phenomena through collaborative research

As with the previously mentioned project, research and development, including basic research, are often carried out together with companies where students are also involved. At Waseda University’s department of modern mechanical engineering, more than 90% of master’s degree students become employed after graduation. The experience of having engaged in commissioned and/or collaborative research from companies becomes a very strong asset. Of course, we cannot immediately announce the outcomes of entrusted collaborative research, and it is also necessary to conceal a device under development, so there is a disadvantage in terms of education. Yet, this can be taken positively that a student is involved in a high-level research and development project, or that they are part of a new, unexplored study. To be honest though, as a man of academia such as myself, there are times when it becomes somewhat frustrating, but this is a secret.

Light-hearted chat with the laboratory students

If you are working with a company in a collaborative research, you may want to take a step or two further after reaching results, even though your partner company may already be satisfied. Even after the collaborative research period has ended, I thoroughly pursue them by delving deeper into the theme for 5, 10 years. Phenomena where companies “do not understand well but can use” are exactly great topics for cutting-edge research. Outsourced/collaborative research is also a great way to become aware of such topics. When working with students to clarify phenomena, the focus becomes very technical, so I try to incorporate a more macro point of view by reconsidering society’s needs for the research.

Towards further energy technology development

It has been 10 years since I began working on heat pumps as my own research topic, and if I count from my heat exchanger work as a student, it has been about 26 years. With thermally driven heat pump control, as I mentioned in Part 1, it has become possible to do something quite sophisticated in simulation using the physical quantity theory. Future societies will most likely increase the number of electrically driven machines. Since it is also possible to predict electric system control with the same simulator, the next aim is to develop theories not limited to heat but including many systems, which will eventually lead to a comprehensive simulator.

Professor Kiyoshi Saito

For example, developing cogeneration that can simultaneously collect electricity and heat requires knowledge on both. Since response speed also differs significantly between electricity and heat, even just controlling it becomes a challenge. Since the research fields of electric systems and thermal systems are separated, connecting this gap could advance the research and development of various energy related equipment in the future.

For this purpose, I am trying to launch a new project in collaboration with mathematics researchers at the University. I am expecting very interesting things to happen when studying both heat and fluids from the perspective of pure mathematics, in addition to knowledge on heat and fluids from actual measurements and mechanical engineering. I will be extremely blessed as a researcher if we can create the driving principle of a completely new heat pump through this collaboration.

Profile

Kiyoshi Saito

Kiyoshi Saito

Professor Kiyoshi Saito graduated from the Mechanical Engineering Department, Faculty of Science and Engineering, Waseda University in 1992. He received his Master’s degree in 1994 and a doctorate in 1997 from the Graduate School of Science and Engineering. He is a Ph.D. professor of Engineering at the School of Fundamental Science and Engineering’s Department of Applied Mechanics and Aerospace Engineering in the Faculty of Science and Engineering. Professor Saito served as a research associate at Waseda University, research fellow at National Institute for Resources and Environment, Agency of Industrial Science and Technology (now the National Institute of Advanced Industrial Science and Technology), and full-time lecturer and associate professor at Waseda University before becoming professor in 2008. He was a visiting researcher at the University of Illinois from 2005 – 2006, visiting professor at the University of the Philippines in 2011, and adjunct professor at the University of Indonesia in 2014.

Professional Achievements

Selected Publications

- N.Giannetti, A.Rocchetti, A.Lubis, K.Saito and S.Yamaguchi, “Entropy parameters for falling film absorber optimization”, Applied Thermal Engineering, 93, pp.750-762 (2016).

- A.Lubis, J.Jeong, K.Saito, N.Giannetti, H.Yabase, M.Idrus Alhamid, and N.V.Nasruddin, “Solar-assisted single-double-effect absorption chiller for use in Asian tropical climates”, Renewable Energy, 99, pp.825-835 (2016).

- N.Giannetti, S.Yamaguchi and K.Saito, “Wetting behavior of a liquid film on an internally-cooled desiccant contactor”, International Journal of Heat and Mass Transfer, 101, pp.958-969 (2016).

- K.Saito, N.Inoue, Y.Nakagawa, Y.Fukusumi, H.Yamada and T.Irie, “Experimental and numerical performance evaluation of double-lift absorption heat transformer”, Science and Technology for the Built Environment, 21(3), pp.312-322 (2015).

- S.Yamaguchi and K.Saito, “Numerical and experimental performance analysis of rotary desiccant wheels”, International Journal of Heat and Mass Transfer, 60(1), pp.51-60 (2013).

Awards and Honors

- Award from Japan Society of Mechanical Engineers (2013)

- Awards from Japan Society for Refrigerating and Air Conditioning Engineers Science (2010, 2012)

- SAREK Best Paper Award(2010)

- ERDT Best Paper Award(2010)