Novel Kiri-Origami Structures Enable High-Performance Stretchable Electronics

Tue, Sep 2, 2025-

Tags

Novel Kiri-Origami Structures Enable High-Performance Stretchable Electronics

Researchers develop hybrid kiri-origami structures that enable the fabrication of high-performance stretchable electronics using non-stretchable materials

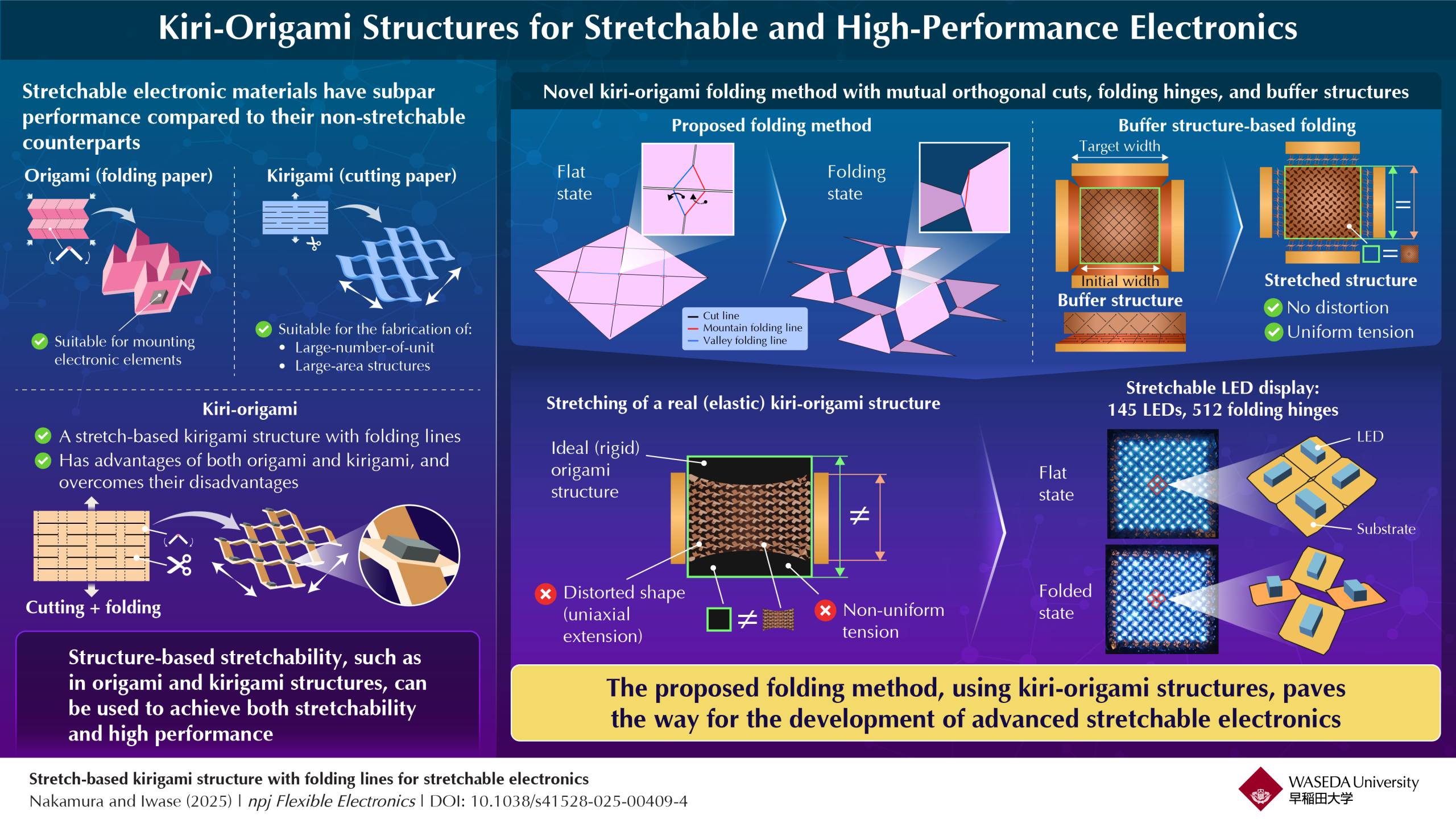

Stretchable electronics have broad applications, including wearable sensors and curved displays. However, the electronic performance of stretchable materials is poor in comparison to non-stretchable rigid electronic materials. In a new study, researchers have developed a new technique, using kiri-origami structures, that combines the benefits of both origami and kirigami to achieve stretchable devices with high-performance non-stretchable materials. This innovative technique can lead to the development of advanced stretchable electronic devices.

Stretchable electronics are used in smartphones, smartwatches, curved displays, and wearable sensors. However, stretchable materials like elastomers have lower electrical performance than rigid materials such as metals or semiconductors, creating a trade-off between flexibility and function.

To overcome this challenge, researchers have explored origami and kirigami, traditional Japanese paper folding (ori-) and cutting (kiri-) techniques, as strategies to achieve stretchability even when using non-stretchable electronic materials. Origami uses hinges to create flat, rigid-mountable panels by bending, while kirigami introduces slits for full-structure deformation and is better for large-area designs. However, kirigami is less suited for mounting rigid components.

In a groundbreaking study, Professor Eiji Iwase and Mr. Nagi Nakamura from the Department of Applied Mechanics and Aerospace Engineering at Waseda University, Japan, developed an innovative hybrid technique using kiri-origami structures. “In this study, we have proposed a kiri-origami structure that incorporates both folding and cutting lines, combining the strengths of origami and kirigami while canceling out their weaknesses,” explains Iwase. “This structure enables large-number-of-unit, large area electronic devices, allowing rigid electronic components to be folded by stretching.” Their findings were published in Volume 9 of the journal npj Flexible Electronics on June 05, 2025.

The proposed kiri-origami design features a mutual orthogonal cutting line pattern. In this pattern, triangular joint panels consisting of two folding lines act as hinges and connect two square panels formed by the cutting lines. When stretched from a flat state, the square panels rise and rotate. This opens slits between the panels, ultimately resulting in a Z-shape around the hinges. This structure allows simultaneous mounting of rigid components and stretching to a target shape, while also supporting large-area and large-number-of-unit structures.

In ideal kiri-origami structures, called rigid-origami structures, the panels do not deform, and the hinges rotate frictionlessly. However, for a real stretchable electronic substrate, panel deformation and elastic repulsive forces cannot be overlooked, giving rise to an “elastic origami model.” To investigate these effects, the researchers tested the deformation of a rectangular elastic origami model using a simple stretching method, where the sample is clamped and stretched uniaxially. They observed that the elastic model deformed differently from the rigid model. They found that this difference occurs due to two factors: first, the clamping edges in the rigid model are free edges, while they are fixed in the elastic model. Second, the entire structure distorts while stretching due to non-uniform tension.

To mitigate these effects, the researchers developed a new folding method that introduces buffer structures. The buffer structures are trapezoidal extensions that connect all the edges of the kiri-origami structure to the clamps. The width of the shorter edge of the buffer structures is equal to the initial width of the kiri-origami structure, while the larger edge is set to the target stretched width of the rigid model. When a tensile force is applied, they extend and behave like springs. As a result, the entire structure stretches in two directions, matching the deformation of the rigid model while maintaining uniform tension.

The researchers demonstrated this technique by fabricating a stretchable display with more than 500 hinges and 145 LEDs. All hinges could fold up simultaneously, and the device’s performance was maintained before and after folding.

“Our approach makes it possible to develop stretchable electronic devices that can accommodate complex shapes and do not compromise on performance, including next-generation high-performance wearable sensors, curved displays, and flexible sensors and actuators for human assistance robots,” remarks Iwase.

This kiri-origami technique thus offers a scalable, structurally engineered solution for integrating high-performance electronic materials into flexible, stretchable devices—paving the way for innovative applications in electronics, healthcare, and robotics.

Reference

Title of original paper: Stretch-based kirigami structure with folding lines for stretchable electronics

DOI:10.1038/s41528-025-00409-4

Journal: npj Flexible Electronics

Article Publication Date: June 5, 2025

Authors:Nagi Nakamura1 and Eiji Iwase1,2

Affiliation:

1Department of Applied Mechanics and Aerospace Engineering, Waseda University

2Kagami Memorial Research Institute for Materials Science and Technology, Waseda University

About Professor Eiji Iwase

Dr. Eiji Iwase obtained his Ph.D. in Information Science and Technology from the Graduate School of Information Science and Technology at the University of Tokyo in 2005. He is currently serving as a Professor at the Faculty of Science and Engineering, School of Fundamental Science and Engineering at Waseda University. He has over 200 publications with over 1,000 citations to his name. He was also awarded the Waseda Research Award in 2017 for high-impact publications. Currently, he also leads the Micro & Nano Mechanics Laboratory at Waseda University. His research interests include microfabrication, microelectromechanical systems (MEMS), nano-photonics, and flexible devices.