Unique nanosheet adhesiveness

This study focuses on the medical applications of nanosheets prepared using a polymeric ultra-thin film (nanosheet), and an evaluation of their properties. Nanosheets are free-standing films made of polymers with a thickness of dozens to several hundreds of nanometers. Although there have been various attempts globally to prepare nanosheets, the present study is the first to create a nanosheet from medical polymers, and to discover its utility as a “body bandage (nanoplaster)”.

To prepare the nanosheets described in this study, chitosan, sodium alginate, or poly(lactic acid), which are biocompatible, were used. In addition, the nanosheets have a property in which the adhesiveness increases as the thickness decreases. In other words, by applying a thinner film with the thickness of a bubble, a “super” thin film with ultimate softness can be generated. If the film is soft, it is able to cover the surface of various objects tightly, and can therefore be adhered without the use of glue. Using this unique adhesion mechanism, a nanoplaster that can be applied outside or inside of the body without glue was developed in this study. By applying nanosheets as the substrate of an electrical circuit, in collaboration with domestic and international researchers, we have been developing a next-generation wearable device.

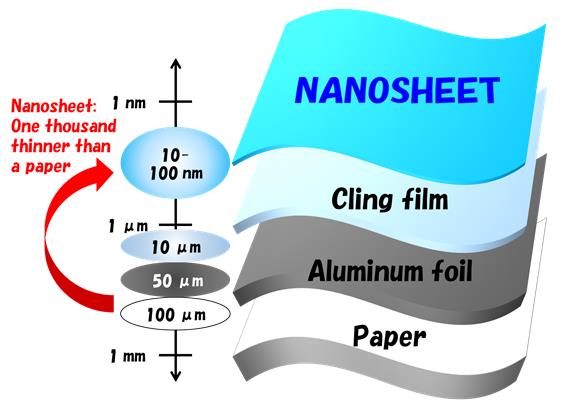

Figure 1: Comparison of the thickness of a nanosheet with various other thin films.

Realizing mass production of nanosheets

Because nanosheets are extremely thin, if left in air on their own, they will be crumpled. Therefore, by layering the nanosheet with a water-soluble film (supporting film), the shape can be maintained. The supporting film will then be dissolved in water before being applied to the skin or an organ.

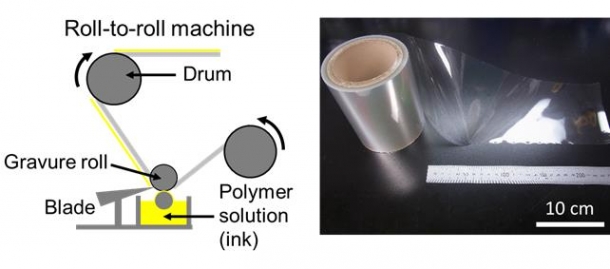

There are two methods used to manufacture a nanosheet. The first is a spin coating method, in which a polymer solution is dropped onto a disc. The disc is then rotated at high speed to disperse the solvent and create a nanosheet. The other is a roll-to-roll method, which applies a printer similar to a rotary press used to print newspapers. With a spin coating method, the number of nanosheets that can be prepared at a time is limited to the size of a single disc (in square centimeters), but with a roll-to-roll method, the raw nanosheet material can be continuously printed along with the supporting film; thus, a large number of nanosheets with large size (in square meters) can be manufactured.

Figure 2: Principle of a roll-to-roll processing machine, and a nanosheet printed on a supporting film. Using a gravure roll and blade, a polymer solution (ink) is printed on the supporting film, allowing for the continuous manufacturing of large nanosheets.

Nanoplaster for protecting organs

As a medical application of nanosheet, we attempted to use a nanosheet to close and repair a defect in a lung that developed owing to a pneumothorax. At present, there are two surgical methods used to close a defect: “an automatic stapler” and “sheet-like fibrin glue” applied to the lesion like a plaster bandage. However, both can damage the areas outside of the defect. When applying fibrin glue, in particular, the presence of the glue can cause adhesion to the other organs. Regarding this point, a “nanoplaster” made of a nanosheet can be applied without glue by utilizing its physically adhesive property, thereby solving the problem.

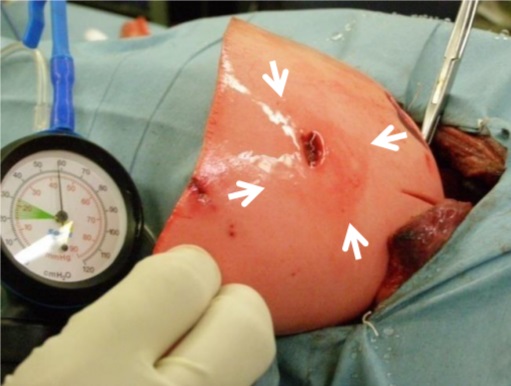

In the experiment, we attached a nanoplaster made of chitosan and sodium alginate over a hole-like defect (diameter of 6 mm) that had opened in the lung of a dog (beagle). After 3 h post application, the nanoplaster became almost invisible, at which time, there was no leakage of air. We also confirmed that the seal was maintained even when the external pressure like sneezing was applied.

We compared a defect in a lung repaired using a nanoplaster with another repaired using fibrin glue after 7 days. We found that, with the nanoplaster, the smooth shape of the lung surface was maintained, and a new blood vessel had formed in the repaired region. In contrast, with the fibrin glue, the chest wall neighboring the lung had become adhered to the repaired defect, requiring an additional surgery to separate them.

The results show that a nanoplaster can be used to repair a pneumothorax without applying fibrin glue. By selecting a proper material consisting of nanosheets, the degradability of the nanoplaster can be tunable to about 1 month. A nanoplaster can be successfully applied, not only for the treatment of a pneumothorax, but also as a protective material for wounds occurring in other organs. At present, we are conducting joint research with manufactures of medical devices and pharmaceuticals, and are in the preparation stage to start clinical trials.

Figure 3: Three hours after applying a nanoplaster to a defect (6 mm diameter) that developed in the lung of a dog (beagle). The nanoplaster was adhered within the area indicated by the arrows (image provided by permission from Wiley-VCH).

Electronization of a nanosheet: Development of electronic nanoplaster

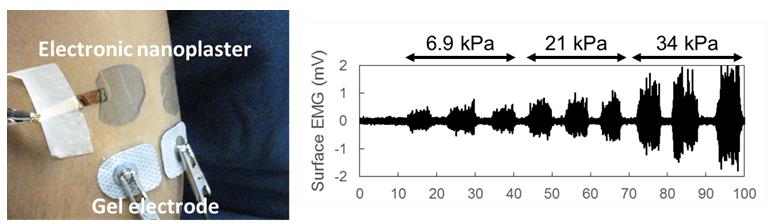

The unique adhesiveness of nanosheets makes them applicable to fields other than medicine. One such application is in the field of wearable devices. First, we considered using nanosheets as electrodes that can be adhered to the skin (joint development with the Italian Institute of Technology). Measuring the biopotential generated when force is generated by a muscle contraction is important in the field of sports science and rehabilitation medicine. However, electrodes used for thorough medical checkups, as an example, are attached to the skin using gel-type glue; thus, the electrodes may fall off owing to the presence of sweat, or may be uncomfortable to the skin, making measurements during natural movements difficult to achieve. Thus, we prepared a nanosheet made of conducive polymers (an electronic nanoplaster). Because conductive nanosheets transmit electricity, they can be used as electrodes.

We attached a traditional gel electrode on the upper arm along with a conductive nanosheet, and measured the surface electromyogram (EMG) during exercise. The values obtained were mostly the same. If nanosheets are used as electrodes, not only are they comfortable, they can also be applied to various parts of the body owing to their softness. Therefore, data can be obtained from parts (e.g., the palm of the hand or sole of the foot) that are not conventional with traditional gel electrodes. In recent years, the analysis of biolocomotion utilizing motion capture has made significant progress. If combined with biopotential measurements using conductive nanosheets, we will further understand the relationship between small movements of the body and related biopotentials. Such technologies will be applicable to athletes participating in the Olympics and Paralympics, and to devices promoting greater healthcare. Furthermore, they will be useful for prosthetics and robots in the future.

Figure 4: Electronic nanoplaster used to measure the surface EMG and actual data. We succeeded to measure changes in the biopotential in response to grip force (6.9–3 kPa). The EMG can be measured for various sites on the body (image reproduced with permission from the Royal Society of Chemistry).

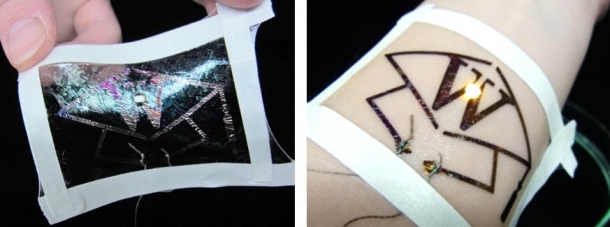

In recent years, with support from other professors at our university (Department of Modern Mechanical Engineering, Iwata Lab/School of Fundamental Science and Engineering, and Micro & Nano Mechanics Laboratory, Iwase Group), we have been developing a skin-contact device in which wiring is printed on a nanosheet. Using nano ink (a solution containing metallic nano particles), we directly printed an electric circuit on a nanosheet using a household inkjet printer, and attached it to an LED in the circuit. Synthetic rubber (poly(styrene-butadiene-styrene)) with elastic property was then used, allowing the nanosheet to act as a substrate for the wiring and adhere tightly to the skin. When this device was adhered to an arm and connected with a battery, an LED was lit on the skin.

Based on our success in lighting the LED, we are now developing an IC card that can be adhered to the skin, such as a public transit IC card (Suica or PASMO). In the same manner, an antenna coil was printed on a nanosheet, and an IC chip was attached, which was successfully recognized by a card reader. Because a nanosheet ticket can remain adhered to the skin, lost IC cards may become obsolete in the future.

Figure 5: A nanosheet equipped with an electrical circuit. After printing an electrical circuit on a nanosheet made of synthetic rubber (poly(styrene-butadiene-styrene)), we turned on an LED attached to an arm (image reproduced with permission from the Royal Society of Chemistry).

Nanosheet platform

We previously attempted to develop surgical plasters and wearable devices by focusing on the method used to manufacture the nanosheets used, as well as an evaluation of their properties and their medical application. Today, we are utilizing such nanosheet characteristics, namely, comfortable for the body, to acquire and regulate biological information.

In the future, by introducing advanced technologies suited to the usage of nanosheets, we hope to develop a platform that connects nanosheets with the body and other object (e.g., sensors, robots, or cells and tissues used for regenerative medicine). In the future, the potential use of nanosheets will likely increase if cooperation with experts of other fields can be promoted.

On the other hand, although this is not limited to nanosheets and is applicable to all scientific researches, we must consider the impact of the advanced technologies we have developed on society and the daily lives of people. Because researchers from various fields are affiliated with Waseda Institute for Advanced Study, we hope to create a safe medical system through further discussions with researchers of not only scientific fields, but also social sciences and the law.

Interview and Composition:Seiko Aoyama/Junichi Tsuchiya

In cooperation with: Waseda University Graduate School of Political Science J-School