A Novel, Single Electrical Pulse Method for the Recycling of Lithium-Ion Battery Cathodes

Environment-friendly energy solutions are essential for the sustainable growth and development of humankind. One such energy solution is the lithium-ion battery (LiB), which offers the advantages of high energy density, high voltage, small size, and long charge–discharge cycles. However, LiBs present a new challenge. In order for LiBs to be truly sustainable, they need to be recyclable. But thus far, there has been a dearth of environment-friendly LiB disassembly and recycling methods. If LiBs could be easily recyclable, they could be the key in supplying the clean electricity needed for a carbon-neutral society.

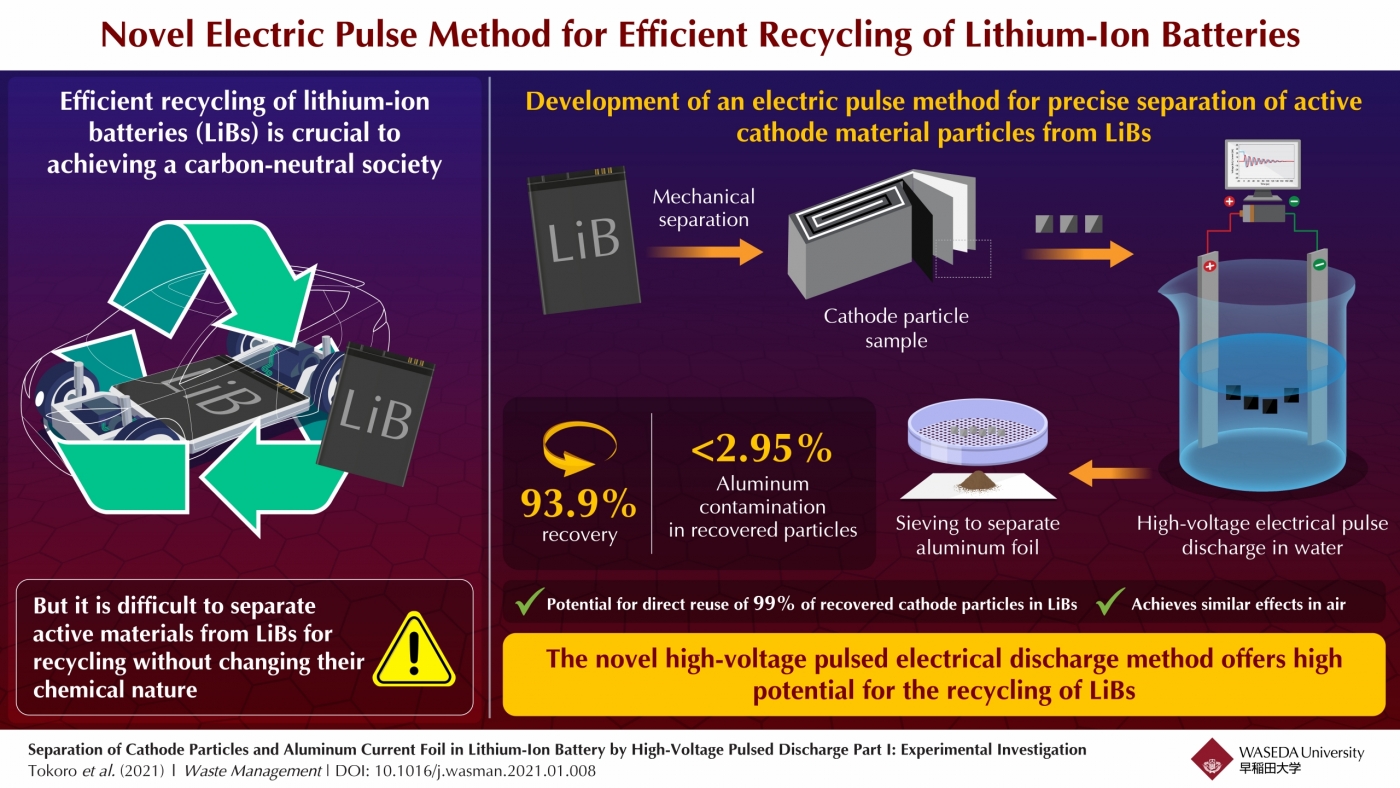

To this end, we developed a novel, high-voltage electrical pulse method to separate cathode active material particles from LiBs, without affecting their chemical composition. As a part of our study, we mechanically separated cathode particle samples from a LiB, cut it into 30 mm x 80 mm pieces, and then placed them in water. The pieces were then treated with a high-voltage electrical pulse from either end in water, causing the active cathode materials to separate from the aluminum (Al) foil that they were attached to. The particles were then separated via sieving, as the Al foil retained its shape.

We found that, at 25 kV, we were able to separate 93.9% of the cathode particles from the Al foil. Further, Al contamination in these recovered particles was less than 2.95%, a value that is low enough to permit further hydrometallurgical processing to recover nickel and cobalt. These values show signs of improvement by scaling up the process. Moreover, almost 99% of the recovered cathode particles retained their chemical composition and form after separation, thereby allowing their direct reuse in LiBs. We further developed a technique based on this method that shows similar separation effects in air.

To better understand the separation phenomenon we performed heat balance calculations on the electrical waveforms. The results suggested that the polyvinylidene fluoride in the cathode adhesive likely melted as a result of Joule heating during the pulse, thereby losing its adhesive properties and allowing the separation of the cathode active materials.

This method has high potential for industrial applications in LiB recycling. Furthermore, the single electric pulsed method developed in this study could also be used to recycle other electronic wastes, such as solar panels and multi-material adhesives.

Link to the original journal article:

https://www.sciencedirect.com/science/article/abs/pii/S0956053X21000131

About the author

Dr. Chiharu Tokoro is a Professor at the School of Creative Science and Engineering, Waseda University. Her research interests lie in environmental materials and recycling technology, environmental remediation, earth resource engineering, and energy sciences. She has published approximately 121 papers in these fields, as well as authored several book chapters. Professor Tokoro has been the recipient of several prestigious awards, such as the 2022 KONA Young Researcher Award and the 2020 and 2021 Waseda Research Awards. Professor Tokoro obtained her PhD from the University of Tokyo in 2003.