A research team at Waseda University has developed indium tin oxide (ITO) electrodes with a new mesh pattern which has high potential for use in flexible electronic devices in the future. Their study was published in Scientific Reports on February 12, 2018.

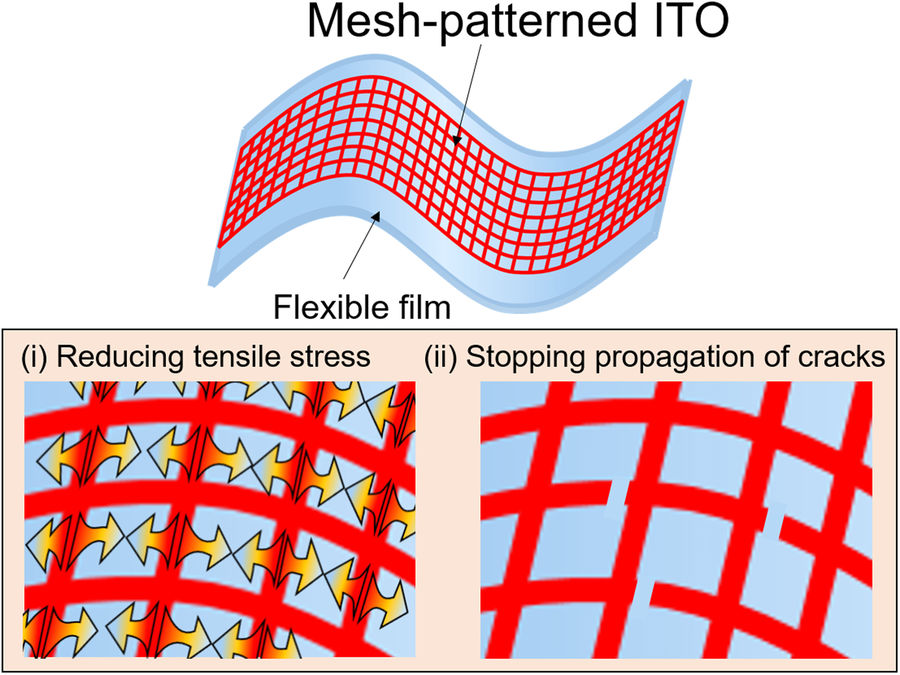

Highly flexible and transparent mesh-patterned ITO electrodes

Flexible electronic devices, including organic light-emitting diodes (OLEDs), touch panels, and organic solar cells, have recently gained attention for their unique properties of being lightweight and having conformability, high mechanical stability, and high formability. Electrodes are important components of these devices, requiring flexibility, transparency in visible light, chemical and physical stability, and favorable electrical properties, such as appropriate work function and high conductance.

ITO, a composition of indium, tin, and oxygen, has been widely used as transparent electrodes owing to its excellent optical transparency, highly electrical conductivity, and appropriate work function. Moreover, ITO electrodes show high chemical and physical durability, as well as high workability. However, conventional ITO electrodes were not suitable as flexible devices since ITO forms cracks due to its rigidity arising from its ionic bonds, which could lead to failure of the devices. Though attempts have bene made to develop ITO-based flexible and transparent electrodes, they have been reported to possess complicated structures or require complex processing.

The researchers at Waseda addressed these issues by creating highly flexible and transparent ITO electrodes with simple mesh structures, fabricated in a two-step process that involves photolithography and wet etching.

“The mesh pattern is effective for preventing ITO from cracking by suppressing stress,” explains Professor Jun Mizuno, professor of nanobioscience and corresponding author of this study. “Even if cracks form, the mesh pattern prevents propagation, meaning that conductivity can be maintained. Furthermore, simulations using the finite element method indicated that the mesh pattern decreased tensile stress by over 10% because of the escaped strain to the flexible film when the electrodes were bent.”

The team also discovered that the resistance increase ratio of mesh-patterned ITO electrodes was at least two orders of magnitude lower than that of planar ITO electrodes when bent 1000 times, Moreover, when evaluated for its electrical conductivity, the density-voltage-luminance (J-V-L) characteristics of an OLED with a mesh-patterned electrode before and after being bent 100 times were the same.

Though consideration from both electrical and optical perspectives will be necessary for further improvement in flexibility, Professor Mizuno says, “Because the mesh patterning is useful to increase flexibility of metal oxides regardless of their rigidity, mesh-patterned ITO electrodes are attractive for use in practical flexible electronic devices in the future.”

Reference

- Highly flexible transparent electrodes based on mesh-patterned rigid indium tin oxide

- Published in Scientific Reports

- Authors: K. Sakamoto, H. Kuwae, N. Kobayashi, A. Nobori, S. Shoji, and J. Mizuno*

*Corresponding author: [email protected] - DOI: 10.1038/s41598-018-20978-x