High performance thin film researcher Professor Tetsuya Osaka

Faculty of Science and Engineering

The “Automated Driving Society” made possible with storage batteries

Professor Tetsuya Osaka’s specializes in the “Development of Advanced Thin Film Materials.” In the last part of this volume, Professor Osaka told us that Japan’s competitive advantage in the increasingly competitive global field of large, high-capacity storage batteries is the development of safe, large storage batteries. In this article, Professor Osaka discusses the implementation of storage batteries in an “automated driving society” with electric vehicles and other technology that lower energy costs.

The “Automated Driving Society” made a reality thanks to large storage batteries

In 2011, the global market of storage battery-related industries was worth 5 trillion yen. The Ministry of Economy, Trade and Industry, estimates the market to grow to over 20 trillion yen by 2020. In order for Japan’s industry to go further, it is very important to secure a share a 50% market share.

In order to reach this goal, we must develop storage batteries with higher capacity, higher efficiency, and higher output. It is essential to devise an electrode material to improve the performance of lithium ion batteries. By replacing the conventional negative electrode that uses carbon with a negative electrode that uses a compound of tin and silicon and adding sulfur to the positive electrode, we have successfully increased the amount of charge and discharge to 1.7 times that of conventional batteries. We hope to continue to improve performance up to approximately seven times that of conventional performance.

NEDO (New Energy and Industrial Technology Development Organization) intends to increase performance of lithium ion batteries for electric vehicles to around twice that of conventional performance, or 300 Wh (watt-hours) per kg mass of the battery .In terms of vehicle travel, this is an increase from 200 km to 400 km. If an electric vehicle can travel from Tokyo to Osaka effortlessly, it will spread throughout the market very quickly.

The weakness of electric vehicles is their price and initial costs. Still, maintenance costs are lower than for gasoline-powered automobiles. This makes introducing electric vehicles less expensive in terms of total cost. For industries that require multiple vehicles for business activities, electric vehicles will lead to large profits despite the expensive initial cost.

Figure: “Automated Driving – A Destructive Innovation that Changes Everything from Lifestyle to Electric Vehicles” supervised by Professor Osaka (source: Nikkei Business Publications, Inc.)

Reducing energy costs in cities with CEMS technology and storage batteries

If vehicles come equipped with automated driving technology and computer-automated driving is implemented into society and replaces human drivers, I think there will be a shift from personal ownership to shared ownership of automobiles. If that happens, there must be an immediate paradigm shift from gasoline-powered automobiles to the high initial cost but low total cost electric vehicles. Google is focusing on map information services such as Google Maps and Google Earth. I think they are trying to position themselves in the future “automated driving society” as the so-called “OS for vehicles.” High-capacity storage batteries are one of the most important key technologies for electric vehicles, and it may be safe to say that the future of the Japanese industry depends on this technology.

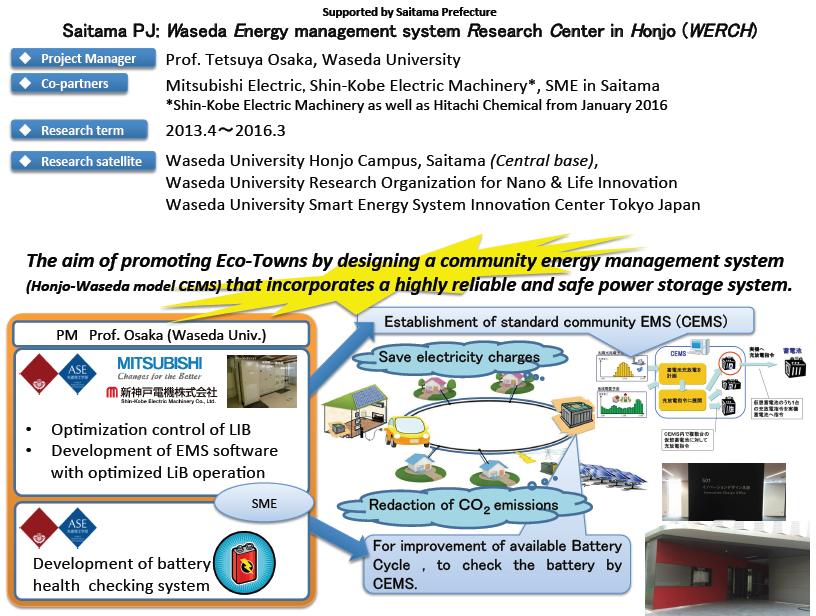

The future led by high-capacity storage batteries is not limited to electric vehicles. At the Waseda Energy Management System Honjo Research Center in Honjo, Saitama prefecture, we are performing research on Community Energy Management System (CEMS), which we hope to realize in the near future.

CEMS is the most efficient management system of electricity in which power-generating and power-storing facilities in a certain area connect with a network of electricity consuming houses and buildings. In collaboration with power companies and large-scale solar plants, the system collects information on electricity demand from each house in real time and uses a storage battery to supply adequate amounts of electricity. The result is significantly reduced electricity consumption for the whole area. We estimate this system can provide battery storage three times more efficient than when installed in each house.

Developing the best batteries with the best equipment in Japan at Waseda University

We are developing storage batteries for a wide range of applications. A big driving force for this development is the “Smart Energy System Innovation Center,” which is located in Building No. 120. Many refer to this center as the “Battery Building.”

Figure and Photo: (left) Exterior image of the Smart Energy System Innovation Center (completed in December, 2014), (right) A stylish area of the building (source: Waseda University Research Organization for Nano & Life Innovation)

Photo: Making batteries in the facility. A booth that explains the process makes it easy for newcomers to understand.

Water is a major part of making lithium ion batteries. In 1999, Waseda University became the first University in Japan to establish a facility with a dry room. Based on that experience, we constructed a Battery Building in early 2015. Although it is small with a floor space of 80 m2, its facilities can manufacture batteries that match the quality of ones in the market. It is capable of producing quality batteries that match battery manufacturer batteries such as pouch-type batteries shaped like a flat plate, can-type batteries commonly used in houses, and button-type batteries commonly used in small liquid crystal equipment. Companies connected to the industry such as Toyota, Toshiba and Panasonic have participated, and we are conducting development and research in collaboration with their affiliate companies.

Other universities have semiconductor chip manufacturing facilities, but Waseda University is the only university in Japan with a facility that manufactures high-capacity storage batteries as large as 5 Ah from the ground up. Around fifteen years ago, we proposed a technology called “Alternating Current Impedance Analysis,” that can evaluate a battery without disassembling the whole product. This analysis technology has a mechanism similar to the body fat scales of sports clubs. Electric signals of different speeds enter the battery and the scale measures this response. It is possible to perform a very precise analysis by analyzing the difference in response. This analysis allows us to measure which material deteriorates in the battery. By utilizing this analysis technology, and by collaborating with manufacturers in Japan, we are trying to develop the world’s advanced batteries and simultaneously establish a mechanism for training the best researchers in the world.

The next article will be the last of this volume. Professor Osaka will talk about the semiconductor biosensor and its medical innovations. Alongside storage batteries, this is another key research field for Professor Osaka.

Profile

Completed course Waseda University, Graduate School of Science and Engineering for a D. Eng. degree in Applied Chemistry (1974).

Postdoctoral researcher at Georgetown University in the United States (1976).

Professor at Waseda University (1986 until present).

Visiting Professor at University of Minnesota (1989).

Dean at Waseda University, Graduate School of Science and Engineering, and Trustee at Waseda University (1998).

Director of Research Promotion Division at Waseda University (2002).

Deputy President at Waseda University (Research Promotion) (2014).

Deputy Dean of Waseda University, Faculty of Science and Engineering (2014).

Chairperson of Waseda University Research Organization for Nano & Life Innovation (2015).

Research

Batteries & Fuel cells

- “New Si–O–C composite film anode materials for LIB by electrodeposition”, J. Mater. Chem. A, 2, 883 (2014)

- “Application of Electrochemical Impedance Spectroscopy to Ferri/Ferrocyanide Redox Couple and Lithium Ion Battery Systems Using a Square Wave as Signal Input”, Electrochim. Acta, 180, 922 (2015)

- “Development of Diagnostic Process for Commercially Available Batteries, Especially Lithium Ion Battery, by Electrochemical Impedance Spectroscopy”, J. Electrochem. Soc., 162, A2529 (2015)

- “Impedance analysis counting reaction distribution on degradation of cathode catalyst layer in PEFCs”, J. Electrochem. Soc., 158, B1184 (2011)

Biosensors & Biomaterials

- “Attomolar detection of influenza A virus hemagglutinin human H1 and avian H5 using glycan-blotted field effect transistor biosensor”, Anal. Chem., 85, 5641 (2013)

- “Sensitive electrical detection of human prion proteins using field effect transistor biosensor with dual-ligand binding amplification”, Biosens. Bioelectron., 67, 256 (2015)

- “Induction of Cell Death in Mesothelioma Cells by Magnetite Nanoparticles”, ACS Biomater. Sci. Eng., 1, 632 (2015)

Magnetic recording devices & Electronic devices

- “A Soft Magnetic CoNiFe Film with High Saturation Magnetic Flux Density and Low Coercivity”, Nature, 392, 796 (1998)

- “Injection of synthesized FePt nanoparticles in hole-patterns for bit patterned media”, J. Magn. Magn. Matter., 324, 303 (2012)

- “Effect of Carbon Inclusion on Microstructure of Electrodeposited Au-Ni Alloy Films”, J. Electrochem. Soc., 158, D403 (2011)