High performance thin film researcher Professor Tetsuya Osaka

Faculty of Science and Engineering

Japan, the kingdom of batteries, will save the world

Professor Tetsuya Osaka specializes in the “Development of High Powered Thin Film Materials.” Utilizing electrochemical nanotechnology, Professor Osaka is working to develop innovative materials that have industrial applications and improve the lives of human beings. The “nano” in nanotechnology refers to a length of 10 to the negative ninth power meters. Although one nanometer is about the size of a single molecule, applications cover a wide range of fields in industry, medicine, and IT. Examples include high-capacity storage batteries in electric vehicles, etc., medical sensors used to measure blood and human tissue, and next-generation hard disc drives. In this volume of Frontline Research, Professor Osaka discusses Waseda University’s goals for the future and its collaboration with industry and government. Waseda University is one of the top Japanese institutions for nanotechnology research.

Growing worldwide competition in development of large, high-capacity storage batteries

In our laboratory, we are developing various advanced thin film materials using electrochemical nanotechnology. Thin film materials is another way to say “plating.” Although plating is an old technology, it is revolutionizing nanotechnology. In particular, our current focus is developing innovative and advanced storage batteries with high energy density, high output and high function.

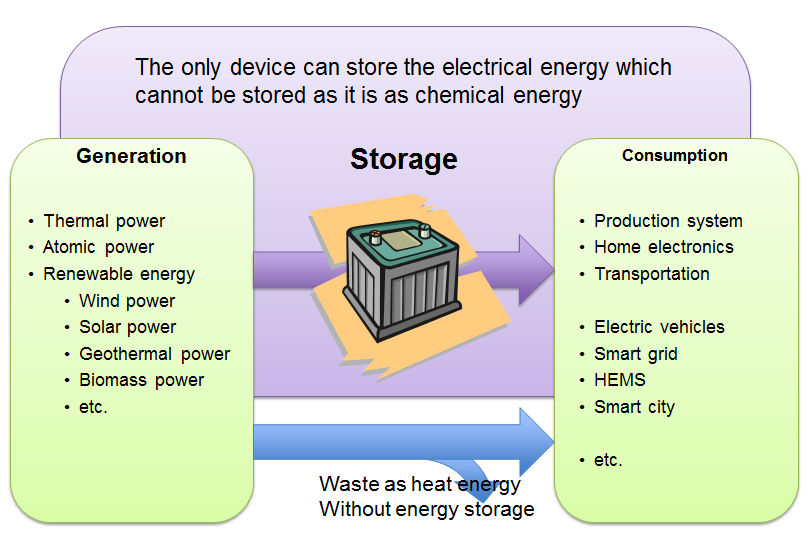

A storage battery is a tool that stores electricity and releases it when needed. Conventional storage batteries had limited capacity, so they were used only in energy supply for small electronic products such as personal computers. In recent years, however, their performance has improved significantly, leading to practical use in a wide range of fields including alternative power sources for automobiles as well as energy infrastructure for hot-water supply systems, illumination systems, and air-conditioning systems for the home and office.

An advantage of storage batteries is that they can store electricity that was generated through methods with low environmental costs (e.g. wind power or solar power), and then use the stored electricity all at once. Since the accident at Fukushima Daiichi Nuclear Power Station caused by the Great East Japan Earthquake, there have been concerns raised about the safety of nuclear power generation. The storage battery industry can offer an energy source with high energy density, high output, and high efficiency. Therefore the industry is expected to continue to grow even more, which is why development is becoming increasingly competitive around the world.

Japan’s competitive advantage is the development of safe large storage batteries

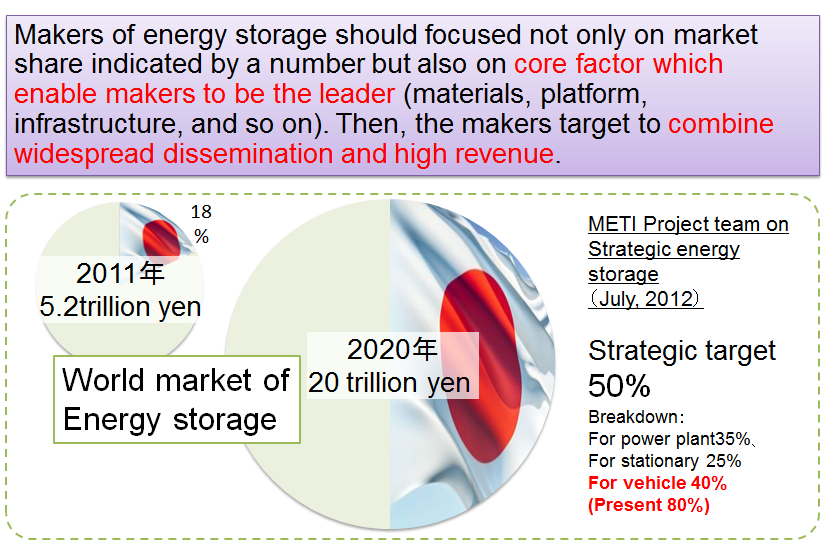

Japan had long been the global leader in storage battery technological development. In 1998, 90% of lithium ion batteries in the world market were produced by Japan. In recent years, however, the technological strength of manufacturers in countries such as Korea and China has improved, and low-cost products have been developed one after another. This led to a decline in the market share of Japanese manufacturers in 2013 to only 32%.

Still, most storage batteries made by Chinese and Korean manufacturers are for personal computers and smartphones, and are small in terms of energy storage. Japanese products still have more than 70% of world market share in large storage batteries used in electric vehicles and other large equipment. Japan’s return as the leader in storage batteries will depend on our ability to develop more advanced products in the future.

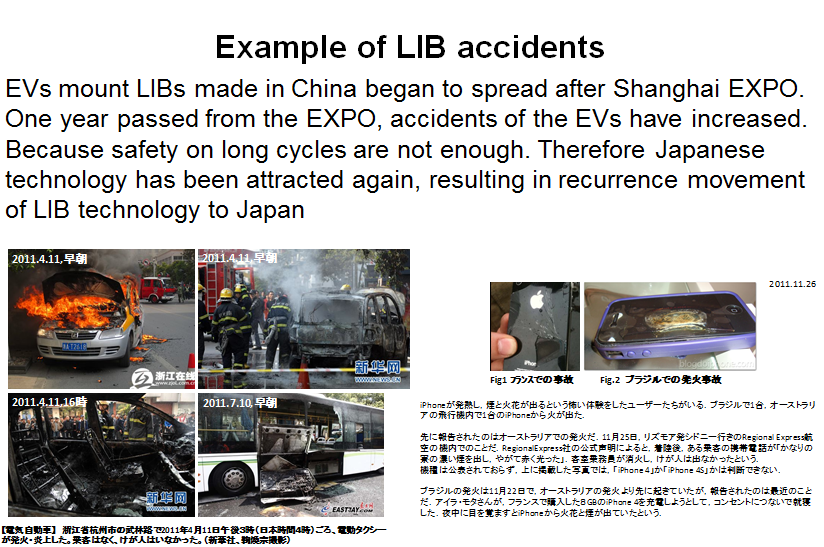

Japan is not the only country focusing on developing large storage batteries. The Chinese government provided support for its storage battery industry in line with the 2010 Shanghai World Fair Exhibition, and is promoting the spread of electric vehicles equipped with industry batteries. However, until around two years after the Shanghai World Fair Exhibition, there were multiple fire accidents involving vehicles equipped with storage batteries developed by Chinese manufacturers. To increaseenergy and output of storage batteries, it is necessary to increase energy density and current output inside the battery. This, however, simultaneously incurs an increased risk of fire and explosion. These incidents demonstrated that Chinese storage battery technology does not meet adequate safety standards.

In the manufacturing stage of nickel metal hydride batteries, it is forbidden to bring alloys into the factory, even if they are as small as a house key. This is common knowledge in Japanese storage battery production lines. This is because metal ions of iron and copper contained in alloy dissipate into the atmosphere. Even though this amount is extremely low, the ions permeate into the product and form a bond with lithium battery electrodes, which leads to fire accidents. Japanese production technology thoroughly eliminates such heavy metal ions in the atmosphere. In addition, to develop large-size storage batteries, there is a need to establish various safety measures in order to decrease the risk of fire and explosion. Japan has a competitive advantage because of its sophisticated production control process designed to meet safety standards. Japan needs to fully utilize this advantage.

In the next article, Professor Osaka will talk about a “future automated driving society” made possible by large storage batteries, and CEMS technology that utilizes storage batteries throughout the city to lower energy costs.

Profile

Completed course Waseda University, Graduate School of Science and Engineering for a D. Eng. degree in Applied Chemistry (1974).

Postdoctoral researcher at Georgetown University in the United States (1976).

Professor at Waseda University (1986 until present).

Visiting Professor at University of Minnesota (1989).

Dean at Waseda University, Graduate School of Science and Engineering, and Trustee at Waseda University (1998).

Director of Research Promotion Division at Waseda University (2002).

Deputy President at Waseda University (Research Promotion) (2014).

Deputy Dean of Waseda University, Faculty of Science and Engineering (2014).

Chairperson of Waseda University Research Organization for Nano & Life Innovation (2015).

Research

Batteries & Fuel cells

- “New Si–O–C composite film anode materials for LIB by electrodeposition”, J. Mater. Chem. A, 2, 883 (2014)

- “Application of Electrochemical Impedance Spectroscopy to Ferri/Ferrocyanide Redox Couple and Lithium Ion Battery Systems Using a Square Wave as Signal Input”, Electrochim. Acta, 180, 922 (2015)

- “Development of Diagnostic Process for Commercially Available Batteries, Especially Lithium Ion Battery, by Electrochemical Impedance Spectroscopy”, J. Electrochem. Soc., 162, A2529 (2015)

- “Impedance analysis counting reaction distribution on degradation of cathode catalyst layer in PEFCs”, J. Electrochem. Soc., 158, B1184 (2011)

Biosensors & Biomaterials

- “Attomolar detection of influenza A virus hemagglutinin human H1 and avian H5 using glycan-blotted field effect transistor biosensor”, Anal. Chem., 85, 5641 (2013)

- “Sensitive electrical detection of human prion proteins using field effect transistor biosensor with dual-ligand binding amplification”, Biosens. Bioelectron., 67, 256 (2015)

- “Induction of Cell Death in Mesothelioma Cells by Magnetite Nanoparticles”, ACS Biomater. Sci. Eng., 1, 632 (2015)

Magnetic recording devices & Electronic devices

- “A Soft Magnetic CoNiFe Film with High Saturation Magnetic Flux Density and Low Coercivity”, Nature, 392, 796 (1998)

- “Injection of synthesized FePt nanoparticles in hole-patterns for bit patterned media”, J. Magn. Magn. Matter., 324, 303 (2012)

- “Effect of Carbon Inclusion on Microstructure of Electrodeposited Au-Ni Alloy Films”, J. Electrochem. Soc., 158, D403 (2011)