Adopted for the FY2022 NEDO public offering research and development project

Aiming to demonstrate carbon recycling technology for polyproduction of commodities using seawater, and research and development of applied products

Main points of the announcement

◆Carbon recycling technology is a key technology for achieving carbon neutrality as it facilitates the separation and capture of CO2 for its efficient utilization as a resource.

◆Pilot-scale tests will be conducted to investigate the feasibility of a technology that enables CO2 capture into magnesium carbonate made from seawater toward the goal of achieving practical implementation of carbon recycling technology by 2030.

◆The project is aimed at achieving early social implementation of carbon recycling technology through the polyproduction of high-quality commodities and practical application of magnesium carbonate derivatives, which represent the main products.

On October 26, 2022, the proposal by the research group, with Professor Takao Nakagaki of the Faculty of Science and Engineering, Waseda University (Shinjuku-ku, Tokyo, University President: Aiji Tanaka) as the project manager (PM) and which includes Professor Mitsuyoshi Akiyama of the Faculty of Science and Engineering, Waseda University and others (hereinafter referred to as This Research Group), as well as Noriyuki Shimada of Sasakura Engineering Co. Ltd. (HQ: Osaka-shi, Osaka, Chairman: Toshihiko Sasakura), was adopted by the New Energy and Industrial Technology Development Organization (NEDO) as the project “Carbon recycling technology demonstration and R&D with co-production of multiple valuable commodities by using seawater ” (hereinafter referred to as This Project) in “Development of Technologies for Carbon Recycling and Next-Generation Thermal Power Generation/ Development of technologies for CO2 utilization at NEDO’s R&D and demonstration base/ R&D and demonstration base for carbon recycling at Osaki-Kamijima.

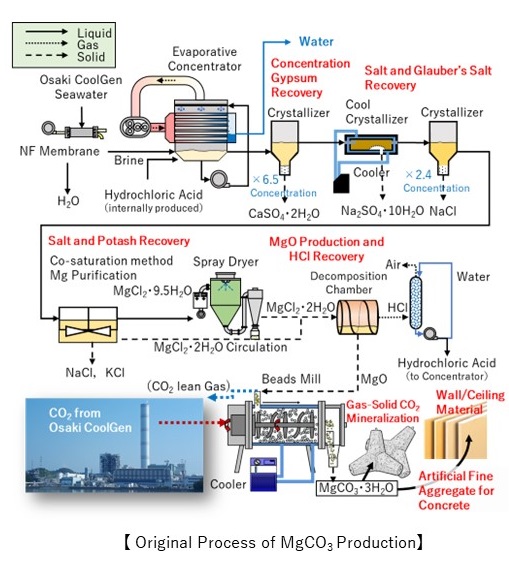

In this Project, pilot-scale tests of carbon recycling technology will be conducted using 20 tons of seawater per day and CO2 derived from Integrated Coal Gasification Combined Cycle supplied in theR&D and Demonstration Base at Osaki-Kamijima , Hiroshima Prefecture. In addition, the research group will develop methods that involve capturing CO2 to form magnesium carbonate, and production methods that involve using magnesium carbonate as an artificial fine aggregate for concrete and wall materials.

(1)Information acquired from previous research (research background)

Carbon recycling technology, which involves the separation and capture of CO2 and the effective utilization of the resulting products as a resource, has been identified as a key technology that can facilitate a carbon-neutral society in the Green Growth Strategy through Achieving Carbon Neutrality in 2050*1, formulated by the Japanese government in June 2021 Roadmap for Carbon Recycling Technologies. *2 was also revised in July 2021.

Elemental technology development and demonstration tests related to the effective utilization of CO2 are being conducted in the research area established in Osaki CoolGen (Osaki-Kamijima, Hiroshima). These tests involve the utilization of CO2 through pre-combustion removal in the Integrated Coal Gasification Combined Cycle to effectively drive the development of carbon recycling technology and achieve practical implementation by 2030. Assessments are being conducted to evaluate the economic efficiency and CO2-reduction potential of this technology.

(2)New concepts to be facilitated by this Project

This Research Group and Sasakura Engineering Co. Ltd, together with JGC Holdings Corporation, were selected for the following NEDO FY2020 public offering projects: Development of Technology for Carbon Recycling/Next-Generation Thermal Power Generation, Development of Technology for Practical CO2 Emissions Reduction/Effective Utilization, and Development of Technology to Utilize CO2 for Carbonate, Concrete Products/Concrete Buildings (hereinafter referred to as Previous Project). These projects were implemented from FY2020 to FY2021.

In the Previous Project, valuable resources, such as soft water, high-purity gypsum, sodium sulfate, table salt, and potassium fertilizer, were produced using seawater, and magnesium oxide was obtained through magnesium chloride hydrates. Thus, the Previous Project successfully achieved CO2 capture to form magnesium carbonate through gas-solid contactor using laboratory-scale test equipment.

This Project will address the following issues and build upon the outcomes of the Previous Project to conduct a pilot scale in the R&D and Demonstration Base for Carbon Recycling at Osaki-Kamijima

◆This Project will demonstrate the technology for the capture of CO2 to form magnesium carbonate by adopting a new process based on the co-saturation method developed in the Previous Project. The method will be combined with a grinding mineralization technique that uses a bead mill and will be initiated using locally sequestered CO2 and 20 tons of seawater per day.

◆The resulting magnesium carbonate will be used as artificial fine aggregate for concrete and wall materials, and the production methods for these materials will be developed simultaneously.

◆A feasibility study is underway to evaluate the mass and heat balance and economic viability of CO2 sequestration, based on the assumption of a seawater desalination plant established in a domestic thermal power station, and integrate this system with a CO2 capture system in the same thermal power station.

(3) Outcomes expected from this Project

This Project will be a significant step towards achieving carbon recycling through semi-permanent sequestration of CO2 to form magnesium carbonate. The feasibility study will also include a detailed assessment of the economic evaluation of both CAPEX and OPEX associated with the developed process, evaluation of the marketability of co-products and carbon recycled products, and the CO2 reduction potential that takes into account the marketability of the products. It is anticipated that the outcomes of the economic and marketability evaluation, as well as the evaluation of CO2 reduction potential will pave the way for early social implementation of carbon recycling technology through monetization. Furthermore, this Project will contribute to achieving local carbon neutrality while simultaneously addressing the rising demand for freshwater abroad that has resulted from climate change.

(4) Role of each organization

【Waseda University】

(Cooperative company) Yoshino Gypsum Co., Ltd.

◆Nakagaki Laboratory

Responsible for fine-tuning the operating conditions of the whole system, especially for the processes of the thermal decomposition of magnesium chloride hydrate and subsequent gas–solid contact carbonation to obtain the crystalline structure of magnesium carbonate required for the final product. Yoshino Gypsum will manufacture the prototypes and evaluate the quality of the resulting high-purity gypsum and magnesium carbonate.

◆Akiyama Laboratory

Responsible for developing concrete that contains a high percentage of magnesium carbonate. In particular, the laboratory will develop artificial fine aggregate for concrete using appropriate materials, such as magnesium carbonate, and explore compounding conditions to achieve equivalent or superior strength to that of conventional concrete products.

【Sasakura Engineering Co. Ltd.】

Responsible for EPC (engineering, procurement, and construction) and continuous operation of a 20 tons/day seawater plant at the R&D and Demonstration Base for Carbon Recycling at Osaki-Kamijima, Hiroshima Prefecture. This company will also enhance the technology line-up through simultaneous development and demonstration of optional processes, such as the suppression of hydrochloric acid generation and polyproduction of calcium carbonate. Further, they will conduct a feasibility study on a full-scale plant, assuming application to domestic thermal power generation with post-combustion CO2 separation and capture.

(5) Nakagaki PM (Project Manager) comments

Carbon dioxide Capture, Utilization, and Storage (CCUS) *3 is an efficient measure to address the issue of CO2 emissions resulting from the use of fossil fuels, which is crucial for achieving carbon neutrality. Carbon recycling is a core technology and is identified as one of the 14 sectors incorporated in the Green Growth Strategy. However, in view of some factors, such as cost and additional energy consumption, it will take time for hydrogen-based carbon recycling products to replace the conventional products. Therefore, among carbon recycling products, carbonated products without use of hydrogen are expected to play a leading role by 2030.

In 2015, the Nakagaki Laboratory invented a draft of the technology for the capture of CO2 to form magnesium carbonate using seawater desalination plant brine. Thereafter, laboratory-scale tests were conducted at Waseda University Nishi–Waseda Campus (Shinjuku-ku, Tokyo), and they now look forward to pilot-scale demonstration tests. The tests were aimed at early social implementation of carbon recycling technology through polyproduction of high-quality commodities and commercialization of magnesium carbonate derivatives, which will serve as the mainstay products. In addition, they plan to supply water to overseas regions struggling with water scarcity, thereby contributing to both water supply and CO2 capture.

* First announced at the GHGT-14 (held in Melbourne in October 2018) sponsored by the IEA (International Energy Agency). The proceedings were released in April 2019. Feasibility Study of Net CO2 Sequestration Using Seawater Desalination Brine with Profitable Polyproduction of Commodities https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3365716## (Patent pending: Patent 2019-080243 “Carbon dioxide sequestration method”)

(6) Information on project names

Project name: NEDO Development of Technology for Carbon Recycling/Next-Generation Thermal Power Generation, Development of Technology in CO2 Effective Utilization Base, Development and Demonstration of Technology to Utilize CO2 in the R&D and Demonstration Base Area

Topic: Carbon recycling technology demonstration and R&D with co-production of multiple valuable commodities by using seawater

Implementation period: 3 years, from FY2022 to FY2024

(Reference) Decision on the implementation systems for Development of Technology for Carbon Recycling/Next-Generation Thermal Power Generation, Development of Technology in CO2 Effective Utilization Base, Development and Demonstration of Technology to Utilize CO2 in the Research Base (Demonstration Research Area) https://www.nedo.go.jp/koubo/EV3_100252.html

(7) Information on participating (joint research) core/researchers

◆Waseda University

・Professor Takao Nakagaki, Department of Modern Mechanical Engineering, School of Creative Science and Engineering, Faculty of Science and Engineering

・Professor Mitsuyoshi Akiyama, Department of Civil and Environmental Engineering, School of Creative Science and Engineering, Faculty of Science and Engineering

◆Sasakura Engineering Co. Ltd.

Noriyuki Shimada, Director of Research and Development Office, Research and Development Department

(8) Glossary

*1:Green Growth Strategy Through Achieving Carbon Neutrality in 2050

In October 2020, the Japanese government announced that Japan aims to achieve carbon neutrality by 2050. Thus, in June 2021, the Ministry of Economy, Trade and Industry and related ministries joined forces to achieve carbon neutrality by 2050 and formulated an industrial policy, known as the Green Growth Strategy, to create a virtuous cycle for both the economy and the environment. Fourteen priority areas where growth is expected were selected with the aim of facilitating innovation and social implementation of innovative technology. High targets were set for each area, and this strategy is considered as a new growth strategy for Japan.

※Reference Ministry of Economy, Trade and Industry

https://www.meti.go.jp/policy/energy_environment/global_warming/ggs/index.html

*2:Roadmap for Carbon Recycling Technologies

Targets, technological issues, and timeframes were established for the carbon recycling technology formulated by the Ministry of Economy, Trade and Industry and other ministries in June 2019, with the aim of expanding and disseminating these technologies and accelerating innovation. They were partially revised in July 2021 based on the formulation of the Green Growth Strategy through Achieving Carbon Neutrality in 2050 in June 2021. The following points were incorporated into the revision: (1) Addition of new technological fields where progress has been made (DAC, synthetic fuels), (2) The commencement of the dissemination of carbon recycled products (general-purpose products) has been rescheduled to around 2040, and (3) Addition of approaches for international collaboration.

※Reference

Ministry of Economy, Trade and Industry

https://www.meti.go.jp/press/2021/07/20210726007/20210726007.html

*3:CCUS

CCUS refers to the process of separation and capture of CO2 emitted by facilities, such as power stations and factories, and its storage in underground reservoirs or for use in products containing carbon. In Japan, 300,000 tons of CO2 has been injected underground at Tomakomai-shi, Hokkaido. Other projects, such as synthetic fuel for aircraft (Sustainable Aviation Fuel: SAF) involving the use of CO2 as a raw material, are also in progress.

※Reference

Agency for Natural Resources and Energy

https://www.enecho.meti.go.jp/about/special/johoteikyo/ccus.html